Butler Panlastic Sealant for Your Roof System

Butler Panlastic – it’s in the testing of butyl rubber sealants for your roof system that provides proof that something as simple as the use of a particular sealant can help ensure a longer life for the buildings in your facility. With Butler Buildings, you are ensured that every detail of your pre-engineered building is tested and held to the highest standard. The difference is in the details. Butler Building components are designed for strength, durability, longevity, and sustainability.

This specialty sealant manufactured by the company helps creates the high-quality, weather-tight seal for the MR-24 Roof Panels, the VSR II Roof Panels, and the Butlerib II Roof Panels.

Types of Butler Panlastic Sealants

Types of Butler Panlastic Sealant

What Makes A Sealant Strong?

There are three main components of butyl tape sealant: butyl rubber, chalk or talc filler, and a softening medium. Butler sealants contain a higher percentage of butyl rubber than any other product on the market. The higher percentage of butyl rubber will create a higher elasticity. Elasticity is the ability of a material to resume its normal shape after being stretched or compressed. Another word to describe this feature is its stretchiness. Butler Panlastic sealant is of the highest quality.

Also, its sealant recovery is over 80 percent. The recovery is directly related to the elasticity of the sealant. The elasticity of the sealant is what determines how long it will stay pliable between two pieces of steel.

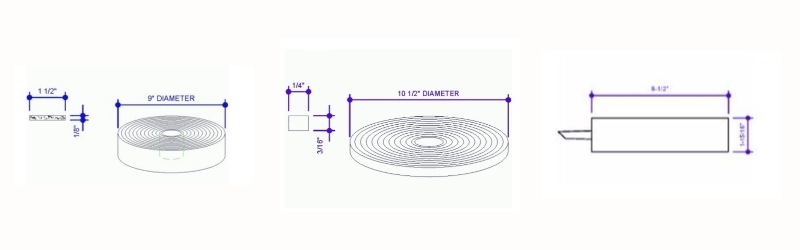

Butler Panlastic is manufactured with spacer beads or cubes embedded in the sealant. These small nylon spacer beads or cubes help to ensure the correct amount of sealant is used upon assembly. Additionally, the beads help to account for temperature differences during installation. Regardless of the temperature, the beads will seek the correct thickness every time.

Watch the video below to see how an expert runs a simple test to show the recovery of both a standard sealant versus the Butler Panlastic sealant. Butler’s sealant recovery is over 80 percent!